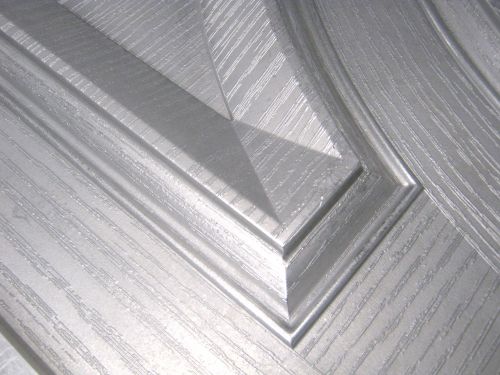

All RTM panels are molded in house. SMC panels are molded offsite. Both processes allow us to recreate the look of a wood panel door in minute detail at a very competetive price compared to high end wood doors. Resin flows through a fiberglass mat to create a panel with a .090 thick wall. While the resin picks up fine details in the molds, the fiberglass mat creates strength. The combined materials form an exterior skin that is virtually impervious to impacts. The interior skin is formed from embossed metal. The core is then injected with a high R-Value, Polyurethane foam. Polyurethane foam has excellent insulating properties, it is also a very effective adhesive, adhering to both the outside and inside skins. This sandwich of materials creates a door section that is extremely rigid yet has the curb appeal that many homeowners prefer.

Back to Product Info